| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : BD

Model Number : customers' requirement

Certification : ISO9001/SGS

Place of Origin : Weifang,China

MOQ : 10 pcs

Price : USD10-40/PCS

Payment Terms : T/T, L/C, D/A, D/P, Western Union, MoneyGram

Supply Ability : 5000PCS/MONTH

Delivery Time : 25-30days/according to order quantity

Packaging Details : Wooden box outsourced with white foam inside

Material : SSiC or SiSiC

Application : Industrial Ceramic

Shape : Customized

Type : Ceramic Tubes

Color : Black,Grey

Sic content (%) : 85%Min

Raw material : Silicon Carbide Powder

Size : Size Customized

Working temperature : 1380℃

Usage : Semiconductor/Kiln

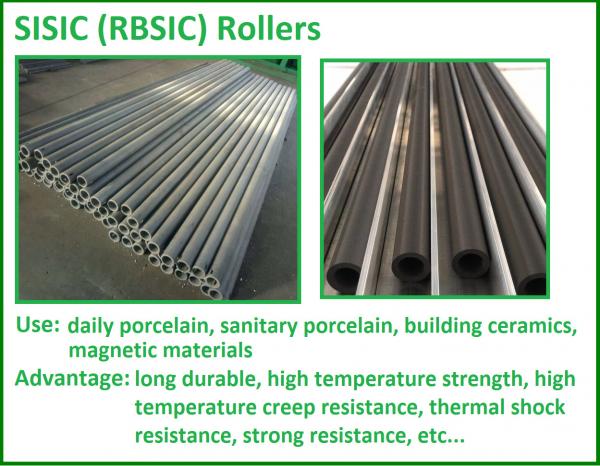

High temperature burning silicon carbide ceramics rollers for industry kiln and building ceramics

Silicon Carbide ceramic Roller for kiln furniture / RBSIC roller / SISIC roller Property:

Reflect sintered silicon carbide roller

1. High temperature strength

2. High temperature creep resistance

3. Good thermal shock resistance

4. Good thermal conductivity and high thermal efficiency

5. Quick cold and hot

6. Corrosion resistance and oxidation resistance

7. High hardness, good wear resistance

8. Do not fall dirty slag, do not pollute burned products

9. High bending strength, not easy to bend and deform

10. Long service life

With its unique formula and technology, the sintered silicon carbide roller is 3-5 times of the silicon oxide roller in terms of thermal shock stability and high temperature load resistance, and its price is only 20%-25% of that of the recrystallized silicon carbide.

Range of Sisic roller's application

The sinter sic roller is mainly used in roller kiln for daily porcelain, sanitary porcelain, construction porcelain and magnetic materials, and sinter sic products can be widely used in electric power, ceramics, kiln, steel, mine, coal, oxidation products, petroleum, chemical industry, wet desulfurization, machinery manufacturing and other special industries.

| SISIC Technical Date | ||

| Item | Unit | Data |

| Max temperature of application | ºC | 1380 |

| Density | g/cm3 | ≥3.02 |

| Open porosity | % | <0.1 |

| Bending strength | Mpa | 250(20ºC) |

| Mpa | 280(1200ºC) | |

| Modulus of elasticity | Gpa | 330(20ºC) |

| Gpa | 300(1200ºC) | |

| Thermal conductivity | W/m.k | 45(1200ºC) |

| Coefficient of thermal expansion | K-1×10-6 | 4.5 |

| Rigidity | 13 | |

| Acid alkaline-proof | Excellent | |

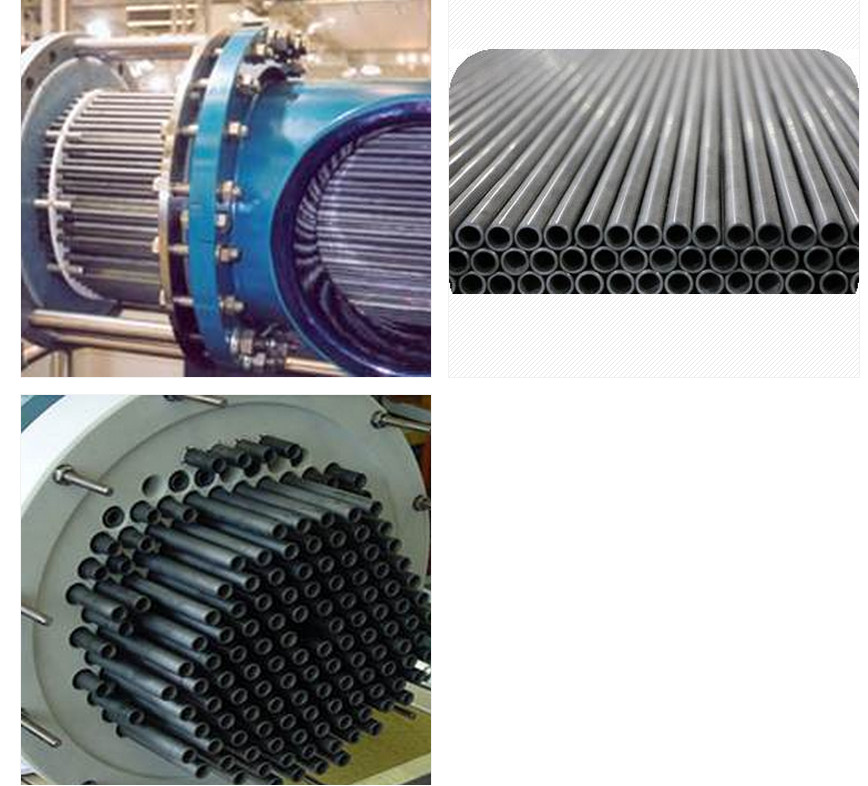

Photos of reference

If you have another question, pls feel free to contact us as below:

Yui

Weifang Better ceramics Co., Ltd

Email:yui@wf-better.com

Weichat:18615910108

TEL:+86-536-2693828

MOB.:+86 18615910108

Factory Address:Hujiazhuang Industrial Park,Gaomi,Shandong,China

Tag:sisic ceramic roller;silicon carbide tube

Rbsic rollers for daily porcelain,sanitary procelain and building ceramics;the factory of silicon carbide ceramics

|

|

High Temperature Burning Sisic Roller For Industry Kiln And Building Images |